Adel here, coming to you live from the LIFCO Content Team. I get to talking to Fraser about this hydraulic pump we had in the shop. See our conversation below and the video to follow.

VIDEO LINK: PVP 33 Troubleshooting

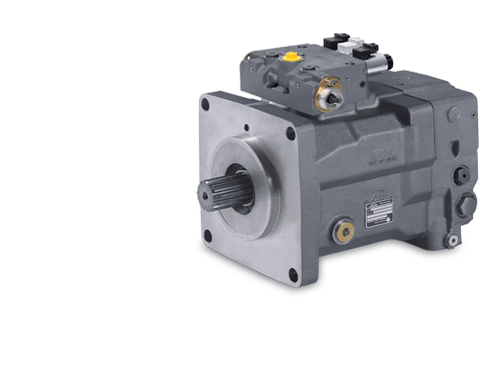

Adel: When a small piston pump is drawing too many amps from its electric motor–like in our troubleshooting video on the PVP 33 – what determines how much torque the motor actually needs to turn the pump, especially when comparing a new pump to a worn one?

Fraser: If the pump draws too much torque, it will stall the motor. The torque draw is based on flow times pressure, plus a constant. When a brand-new pump’s maximum flow and pressure exceed what the motor can handle, the pump ends up limited—let’s say to about 50% of its potential.

Adel: If the pump was pulling more torque than the motor could support, is that what ultimately led to the failure we saw?

Fraser: In our example the pump is limited to 50% of the electric motor, and everything is fine when it’s new. But if the pump gets worn or damaged, then to deliver that same 50% flow it might have to work at 60% of its capacity. That extra 10% ends up going out the case drain. The pressure builds in the rotating group and leaks internally, creating a much larger pressure drop into the low-pressure case drain. That produces a lot of heat.

Adel: When diagnosing that issue, how do you determine that excessive case-drain flow is the cause instead of another type of failure–and in the same system, and why didn’t the same issue occur on the P2?

Fraser: This was the PVP33, not the Rexroth tandem–Mechanical binding can happen, but that usually causes a total failure. Case-drain flow is easy to check—just collect it in a bucket and time it. If anything seems off, pull the pump and inspect it. In this case, the user started the pump without filling the case, which severely damaged the barrel and port plate.

Adel: When we were reviewing this video (PVP33) you mentioned wanting to talk about why an increase in case flow will increase the torque requirement of a pump? I think that's a good question and was wondering if you could explain that more.

Fraser: Yes but it only happens in certain circumstances. If you try to limit the flow or pressure because you are putting the pump on a smaller electric motor than normal, there are times when the pump could draw more torque (i.e. more horsepower) and could stall the electric motor.

Adel: So is that why Lloyd said he was expecting to see heat damage inside of the pump before he opened it up?

Fraser: I'm not sure why he was expecting specifically heat damage. I had mistakenly said in a previous video that overpressurization causes additional wear (and wear produces heat), but I was wrong about that cause/effect. But there was damage in the pump, from a dry start up. A damaged pump that has its pressure limited is the specific scenario that will overtorque the electric motor.

Fraser: You fully understand what I am talking about here? I'm skeptical. 🙂

Adel: I get it. basically giving the pump to much to handle

Fraser: The issue is that the pump, in a standard pressure compensator, is getting a signal from the system pressure telling it to produce flow. So if it is damaged and the pump is internally leaking and going out the case drain, then it needs to pump more to get the same system response. If the pump was not being limited, and was instead doing its max, then its maximum flow would decrease and their machine would be slower. But in this specific case with the pump being limited, nobody would know the pump is working extra hard. Well, until they measure the amperage of the electric motor or see it stall completely.

Megan: Okay yes I am getting it, I think I was just having a tough time to piece everything together. But yeah it all makes sense, the pump was damaged on the inside from a dry startup, and was leaking, so the pump had to work harder to keep up and because it was already being limited it wasn't something you could know which led it to stop working. Thank you for breaking it down.

Fraser: The problem is that the pump does not know how much flow it is producing, it only knows the system pressure and then is reacting accordingly. If it used to get the system pressure it required at 50% flow, but then a bunch of that flow leaks out of the system and out the pump case drain, then it will increase the flow out of the pump. The pump thinks that is going into the system, but it isn't. It's just leaking out. Like the water bucket analogy I used in the video: if you need half a bucket of water moved, but you get a bad knee and keep spilling a quarter of the bucket, then you need to fill the bucket up three quarters of the way. So the bucket is heavier and you end up having to do more work.