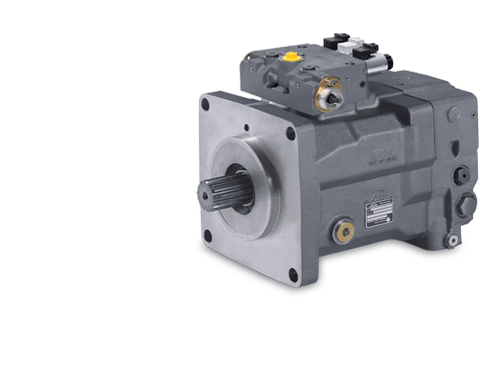

Hi everyone! Megan from the content team again. A customer brought their pump (HPV 280), motor (HMA 280) and charge pump in because they were losing charge pressure. This means they have a closed loop system versus an open loop. I talked with Fraser and he helped break down how closed loop systems work, as well as the importance of proper start up. Read below and be sure to check out the video (linked below) for the whole troubleshooting process.

Video: Why is this pump losing charge pressure?

Fraser: Yes charge pumps are only in closed loop systems. The closed loop has a pump and motor directly connected to each other. Those pumps and motors are highly efficient, but not 100%. So this charge pump puts more fluid into the system to make up for those losses.

Megan: Then what would happen if you didn't have a charge pump, or if it malfunctioned?

Fraser: The very first thing that would happen is that the lower pressure side (the charge side, which is usually around 350 psi) would begin to have a lower pressure. If it goes too low, then the pump would start to be starved of oil and it would run dry.

Then, we would see a loss of lubrication in the pump, and decrease in pump life. At some point the pump will fail and that is when we see the disintegration of parts inside. Because the motor is connected directly to the pump, it would destroy the motor as well. This is why closed looped systems need to have both the pump and the motor inspected at the same time.

Page four has a great diagram PDF with Diagram

Megan: That makes sense so you definitely need to have a charge pump in a closed loop system. So whenever someone has an issue with charge pressure or charge flow would you always ask them to bring in all 3 (pump, motor and charge pump)?

Fraser: The charge circuit is also what provides power to the controls. Meaning if the charge pressure was low then the pump won't be able to turn its swashplate to increase flow (ie. won't be able to turn "on"). It is likely that people are aware of the controls being sluggish or non-responsive. I'm sure most computerized equipment would have a sensor reading on it too, so if it goes under a certain amount then it electronically refuses a command to turn on.

Megan: In the video, the main damage was found on the pump especially on the pistons and there was some minor damage on the motor. Why was it that the pump had more damage? I would figure in a closed loop if it's all connected the motor would show similar damage.

Fraser: The pump is powered by a diesel engine or electric motor. It is drawing fluid from the lower pressure side and will continue to draw whether or not there is fluid there. The motor is receiving the energy from the pump, any problems and it would just stop working.

Megan: The pump will keep running no matter what but the motor will eventually stop, preventing further damage. Now, the conclusion in this one was that poor start up caused the damage and increased leakage. Can you talk about what that means and what a proper startup should look like?

Fraser: In a closed loop pump they need to make sure there is sufficient charge pressure. This is as easy as putting a gauge on the A and B ports. You are making sure the pump is getting enough oil so that its internal parts are lubricated and the controls function properly.

Megan: Making sure the startup goes smoothly is very important. In this case, the poor startup wasn’t identified as the cause until the pump and motor were inspected and damage was found. Do you think this happened because they didn’t know the proper startup procedure, or because they didn’t realize the charge pressure was too low?

Fraser: Startup is important because the pumps are filled with air instead of oil. It can be tricky to get the air out. Sometimes an air bubble can physically block the oil. Just last week we had a P30S, an $80k Gold Cup pump, that we were seeing no charge pressure. When we put a flow meter on the charge pump, we had no flow. When we took the charge pump off and tested it, it worked just fine. Then we re-installed it on the P30S, and we heard a little "pop" and then the charge flow began. Just like with people, sometimes equipment just needs a little patience. This is on an upcoming video, so if you are reading this then I gave away the ending. I'm sorry, but I didn't think anyone was reading these.